Mortar analysis and suggested re-pointing mixes, and general advice on other works required before any repointing is undertaken

We provided advice on how they should proceed to re-point Low Trenhouse Farmhouse in a hot lime mix as required by the contractors client. Our report and mortar analysis suggests what matters should be addressed before the pointing takes place and also suggests an appropriate mix for this building in this location.

Which mortar should be used to re-point this building?

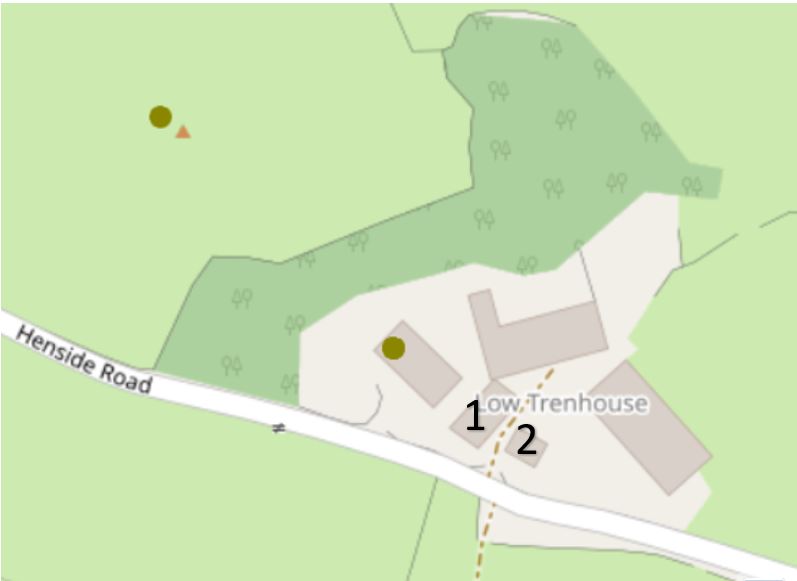

This part of the Malham estate passed in 1852 to the Morrison family, and in 1907 Walter Morrison built the present farmhouse, and the old farmhouse has been put to agricultural uses. However, unlike the old vernacular farmhouse, see diagram 1, with its protective tree belt to the west and north, a front elevation facing away from the worst of the weather, the north-western elevation protected by an agricultural lean to, and no openings in the southwest elevation, it has just been planted in the farmyard. Its design is the same as other buildings of the same date in this area and within England as a whole, it is not designed for the place upon which it sits, and thus was always going to struggle to protect the occupants from the weather conditions in this very exposed location.

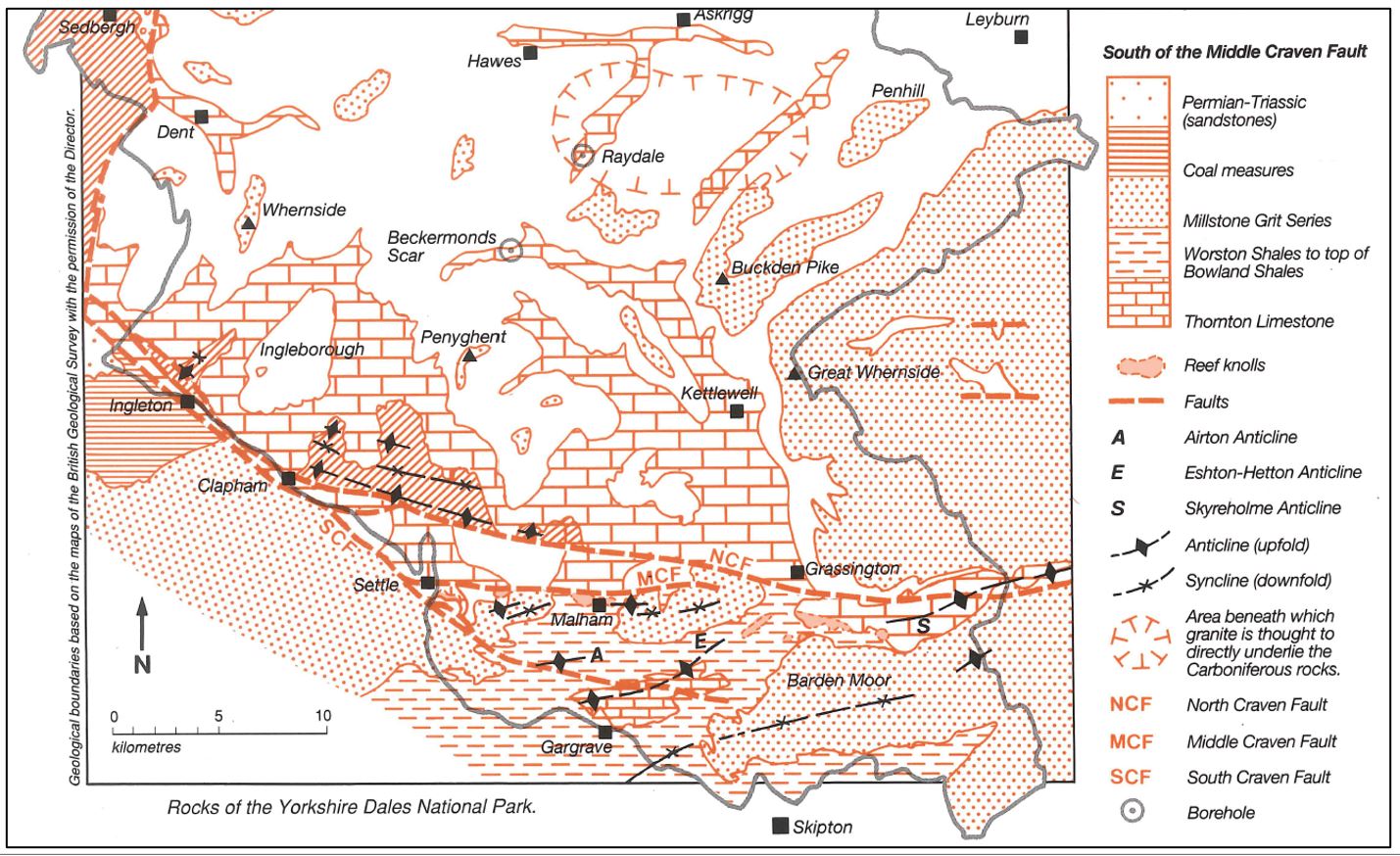

The 1907 farmhouse is built from good quality ‘Thornton Limestone’ which is found upto 200 m deep, in this immediate area. Locally in the Airton Anticline, the limestone rests conformably upon dark grey calcareous mudstone, muddy limestone and calcisiltites of the Clitheroe Limestone Formation, formerly referred to as the Thornton Shales-with-Limestone.[1] The more thinly bedded limestones of this formation were generally quarried principally as a source of lime but were also used locally in field walls and farm buildings along its outcrop. [2] Areas of Namurian Mill Stone Grit were also brought to the surface by the Anticline, see diagram 2 below, and were also quarried locally,[3] and the window and door openings at Low Trenhouse may be carved from this stone.

This dolomitised limestone, is bedded on a mortar comprised of crushed limestone bound by a feebly hydraulic lime binder. The lack of lime inclusions and the accepted practice of the time that stated that a “Lime mortar should be thoroughly mixed to ensure uniformity of composition and left for at least a week before using,” [4] suggests that it was not used as a hot lime mortar.

However, despite perhaps a narrow cavity within the construction water penetrates the walls, especially those which face the prevailing winds. Quite soon after it was built and certainly by 1942, see photo 1 below, it was pointed and ‘slober’ rendered on all but its front elevation with a strong cement mortar. Clinker based OPC’s were available from the Clitheroe area from 1894, where there was a dry process plant designed and owned by Charles Spackman, and the Isis Portland Cement Co. Ltd.[5] . It is suggested that the only way of keeping this wall dry, without destroying some of the faces of the stone from which it is built, would be to slate hang the gable end. This would not be out of character with this building type and wind driven rain in the early 20th century was often prevented from passing through walls by hanging slates on the front faces of the walls.[6] The front elevation exposed to severe weather is more difficult to deal with.

Only once all these issues have been dealt with should the house be repointed, and whilst the usual matrices for construction work are moderately hydraulic lime or Portland Cement,”[8] in 1907, the analysis in appendix 1 suggests that originally a feebly hydraulic lime mortar was used, that is very unlikely to have been used as a hot mix. It would normally be suggested that a mix of 1 part Ionic feebly hydraulic lime, which comes from a similar type of dolomitised limestone found in the Luchon area in the Pyrenees: to 1 part crushed local limestone: to 1 part Leighton buzzard sand, to even out the grading and for workability, be used. However due to the poor siting and design of this building we would suggest that Ionic Old White NHL3.5 be used to replace the NHL 2.

Please note that if a hot lime is used in this location, it will be at least 6 months before it won’t be damaged by heavy wind driven rain, as sufficient portlandite will not have been converted to calcite. It should also be remembered that whilst hydraulic limes become stronger than hot lime mixes over time, they do not form Alite within the mortar structure, as found in OPC based mortar, (Alite blocks pore structures and prevents vapour permeability).

Diagram 1: The old farmhouse (1) and its later 1907 replacement (2) Photos 1 & 2: The building recorded in the National Farm Survey in 1942 and the same building today

Photos 1 & 2: The building recorded in the National Farm Survey in 1942 and the same building today Diagram 2: Geology in the Yorkshire Dales[9]

Diagram 2: Geology in the Yorkshire Dales[9]

[1] C N Waters, R A Waters, W J Barclay and J R Davies, ‘A Lithostratigraphical Framework for the Carboniferous Successions of Southern Great Britain’, BRITISH GEOLOGICAL SURVEY RESEARCH REPORT RR/09/01 (Keyworth, Nottingham: British Geological Survey, 2009), 25–26.

[2] ‘Strategic Stone Study A Building Stone Atlas of North Yorkshire East and York’, 4.

[3] David Johnson, Quarrying in the Yorkshire Pennines An Ilustrated History, 1st ed. (Stroud: Amberley Publishing, 2016), 7–8.

[4] Mitchell, 20.

[5] Peter del Strother, History of Ribblesdale Cement, (Castle Cement Ltd, 2008), 22,32 & 33.

[6] Mitchell, 55.

[7] Mitchell, 57.

[8] Charles F. Mitchell, Building Construction and Drawing, 7th ed. (London: B. T. Batsford, 1906), 20.

[9] Yorkshire Dales National Park, ‘Dales Rocks: Geology and More’, Dales Rocks - Geology in the Yorkshire Dales, n.d., https://dalesrocks.org.uk/.

[10] ‘Strategic Stone Study A Building Stone Atlas of North Yorkshire East and York’, 4.

Bibliography

C N Waters, R A Waters, W J Barclay and J R Davies. ‘A Lithostratigraphical Framework for the Carboniferous Successions of Southern Great Britain’. BRITISH GEOLOGICAL SURVEY RESEARCH REPORT RR/09/01. Keyworth, Nottingham: British Geological Survey, 2009.

Johnson, David. Quarrying in the Yorkshire Pennines An Ilustrated History. 1st ed. Stroud: Amberley Publishing, 2016.

Mitchell, Charles F. Building Construction and Drawing. 7th ed. London: B. T. Batsford, 1906.

‘Strategic Stone Study A Building Stone Atlas of North Yorkshire East and York’, May 2012.

Strother, Peter del. History of Ribblesdale Cement,. Castle Cement Ltd, 2008.

Yorkshire Dales National Park. ‘Dales Rocks: Geology and More’. Dales Rocks - Geology in the Yorkshire Dales, n.d. https://dalesrocks.org.uk/.

Related Articles

The steps members of the Waterton’s Wall restoration team, with support from Mark Womersley, have been following to consolidate, conserve and repair this historic wall that represents the successful efforts of Charles Waterton to preserve the wildlife that lived on his estate near Wakefield in West Yorkshire.

1. Fill deep voids behind the wall’s facing stones with deep pointing work. The works involve …

Mark spent a day recording a historic timber-framed garden building at Woodsome Hall

Mark Womersley, as part of his voluntary work with the Yorkshire Vernacular Buildings Study Group, spent…

M Womersleys were delighted to offer a day of tutoring to those who attended the Wentworth Woodhouse Working Party

M Womersleys were delighted to offer a day of tutoring to those who attended the Wentworth Woodhouse…