It is often useful before starting on the conservation or restoration of a historic building, to understand what materials have been used originally and through the different phases of its life, for the construction, plastering, and rendering. No job is the same and we offer a range of mortar analysis techniques. Often, we will undertake dissolution analysis of the mortars used, and based upon years of interpretive experience, we will detail the type of binders and aggregates used and their ratios and grading. This together with our recommendation for a replacement pointing, building mortar or render/plaster will often be sufficient for many jobs on listed and non-listed buildings and structures.

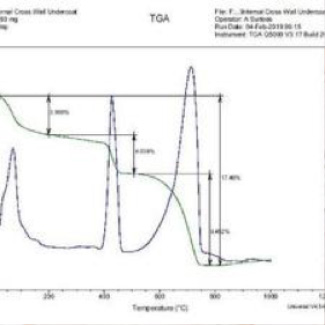

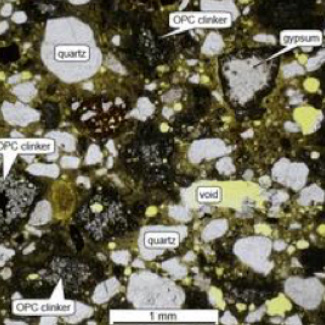

However, when more detail is required to understand the structure within the mortar, and further precise information on its hydraulic and clinker content is needed, additional thermogravimetric and petrographic mortar analysis is carried out.

The most important element of all these investigations is the interpretation of these results and Mark Womersley has over 25 years’ experience of analysing mortars, but as importantly, also has many years’ experience in their subsequent specification and use. This ensures that you not only find out which mortars have been used on your building, but also which ones should be used in future conservation work, that will let the building’s fabric breathe, be flexible enough for the substrates and be durable enough for the buildings location and detailing.

We can also prepare sample panels, or advise your contractors on which mortars to use and what options they have for creating different finishes and textures.

M. Womersleys works with a local University using the state-of-the-art equipment and techniques.