The steps members of the Waterton’s Wall restoration team, with support from Mark Womersley, have been following to consolidate, conserve and repair this historic wall that represents the successful efforts of Charles Waterton to preserve the wildlife that lived on his estate near Wakefield in West Yorkshire.

1. Fill deep voids behind the wall’s facing stones with deep pointing work.

The works involve the careful removal of loose building mortar with scutch, plugging chisels and lump hammers, which appear to have large voids behind them and the adjacent stones. If a large void is found, the space is flushed out with clean water, using watering cans, churn brushes in buckets of water or by using garden pump sprayers. This ensures that loose debris and dirt that would prevent mortar from consolidating the wall and successfully filling the voids is removed, and that the space is damp to help the mortar cure.

Following the preparation work, a stiff mix of hydraulic lime mortar is forced into the void using narrow pointing irons, and where possible, small pieces of clean sandstone are pushed into the filling mortar once it is in the wall to give it better structure and to support the wall's stonework better. The mortar used is made up of one part Ionic Old White Naturally Hydraulic Lime (NHL 3.5), one and a quarter parts Brown/Grey Nosterfield washed river sand, and one and a quarter parts golden-yellow, iron-rich, Leighton Buzzard sand and clean water. The mortar is finished approximately 15 to 20 mm from the surface of the stone to allow it to be repointed over.

2. Repoint the wall where mortar is missing or badly eroded

As above, the works involve the careful removal of loose building mortar with scutch, plugging chisels and lump hammers, taking unsound mortar back to old solid building mortar and at least 25 mm back from the face of the stone. Starting from the top and working down the wall, all the loose debris is washed out of the joints and down to the base of the wall. Making sure to go right to the ground to ensure stains are not left on the wall below. Watering cans, churn brushes in buckets of water and garden pump sprayers are used. This ensures that loose debris and dirt that would prevent mortar from adhering to the stone are removed, and that the space is damp to help the mortar cure.

Following the preparation work, a stiff mix of hydraulic lime mortar is forced into the void using pointing irons that are slightly narrower than the joints being filled. The mortar used is again made up of one part Ionic Old White Naturally Hydraulic Lime (NHL 3.5), one and a quarter parts Brown/Grey Nosterfield washed river sand, and one and a quarter parts golden Leighton Buzzard sand and clean water. The mortar is not overworked in the joint and left slightly proud of the stone, but not smeared onto the face of the wall. After half an hour to four hours, depending on how warm and damp the weather is, the firmed-up mortar is stippled back by hitting it with the bristles of a dry churn brush. After another hour or two, the mortar can be brushed off to expose the aggregate and its natural texture.

3. Repairing the badly eroded stone with lime-bound ‘plastic mortar’

Where the structure of the sandstone walling has badly eroded beyond 20 mm from its face, the surface voids have been filled with a traditional lime-based plastic stone repair. This type of repair has been used since the end of the 19th century to help conserve walls and ensure the minimum amount of original fabric is lost during restoration works.

The eroded surface is cleaned back to remove green organic growth. Using scutch chisels and limp hammers, the area to be filled is given straight, slightly undercut edges of at least 5 mm to fill to, to avoid ‘feathering out’ the mortar that is being used, as this will fall off during severe winter weather.

The mortar used for backing out deep hollows in the stonework comprises one part Ionic Old White Naturally Hydraulic Lime (NHL 3.5), one and a quarter parts Nosterfield washed river sand, and one and a quarter parts Leighton Buzzard sand and clean water, with 15 % Prompt natural cement added just before use. This deep filling is then finished with 15 to 20 mm of a premixed, pre-coloured ‘Womersleys Stone Repair’ material called ‘Yorkshire’, which is just mixed with water to a very stiff, almost chewing gum consistency. It is forced against the undercoats or the stone directly with small tools and left 3 mm proud of the final wall surface. The following day, it is scraped back with small tools, ‘Lions Feet’ and coarse wet and dry paper to shape and texture it to blend in with adjacent stone. At this stage, it can also be coloured with tiny amounts of Yellow and Black Iron Oxides mixed with clean water.

Related Articles

Conservation cleaning, metal work and masonry repairs at the cemetery of St John the Divine

M Womersleys have just finished assisting students and tutors with conservation cleaning, metal work…

Guidance Sheet for burning lime, quenching, slaking and using lime for conservation work in Antigua

M Womersleys Ltd assisted the Harrison Centre to allow them to construct an active lime kiln in their…

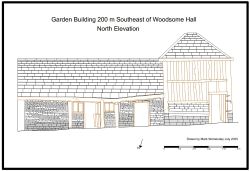

Mark spent a day recording a historic timber-framed garden building at Woodsome Hall

Mark Womersley, as part of his voluntary work with the Yorkshire Vernacular Buildings Study Group, spent…

.JPG)