Guidance Sheet for burning lime, quenching, slaking and using lime for conservation work in Antigua

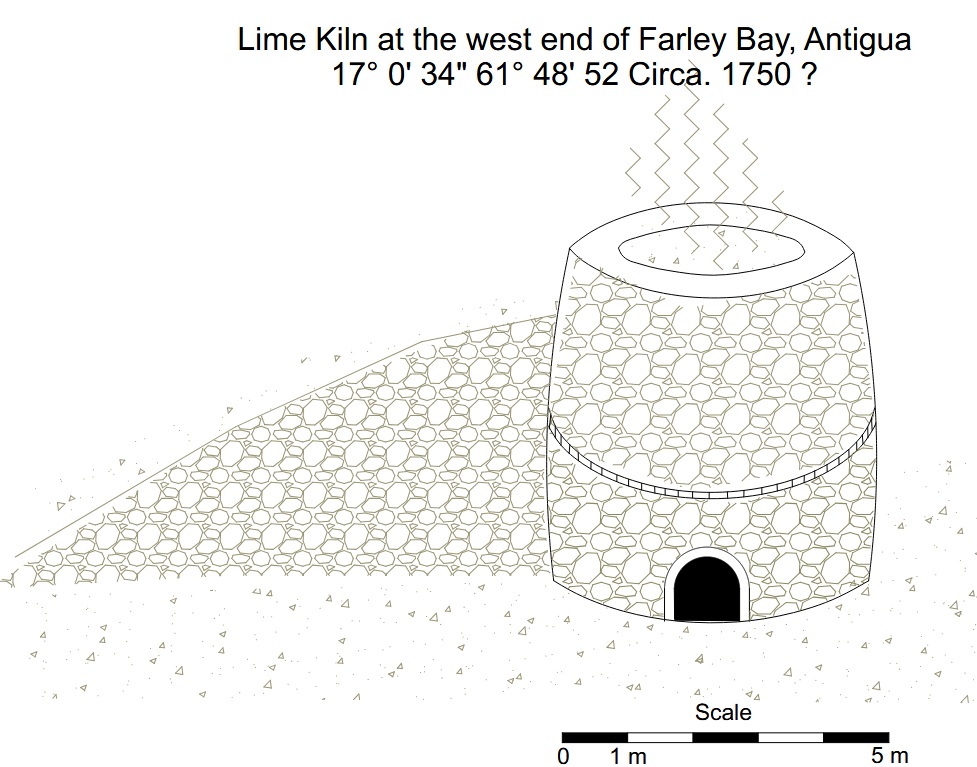

M Womersleys Ltd assisted the Harrison Centre to allow them to construct an active lime kiln in their school grounds. The 1 ½” limestone was sourced from the Burma quarry just southeast of the main Airport on the island. The charcoal and charcoal waste used were sourced from the island and called ‘coal’ and ‘waste’. This follows a tradition of a more remote lime kiln at the west end of ‘Farley Bay’ in Antigua, which sits in an area reclaimed by nature. Nearby, we found piles of coral ready for burning and a charcoal preparation area.

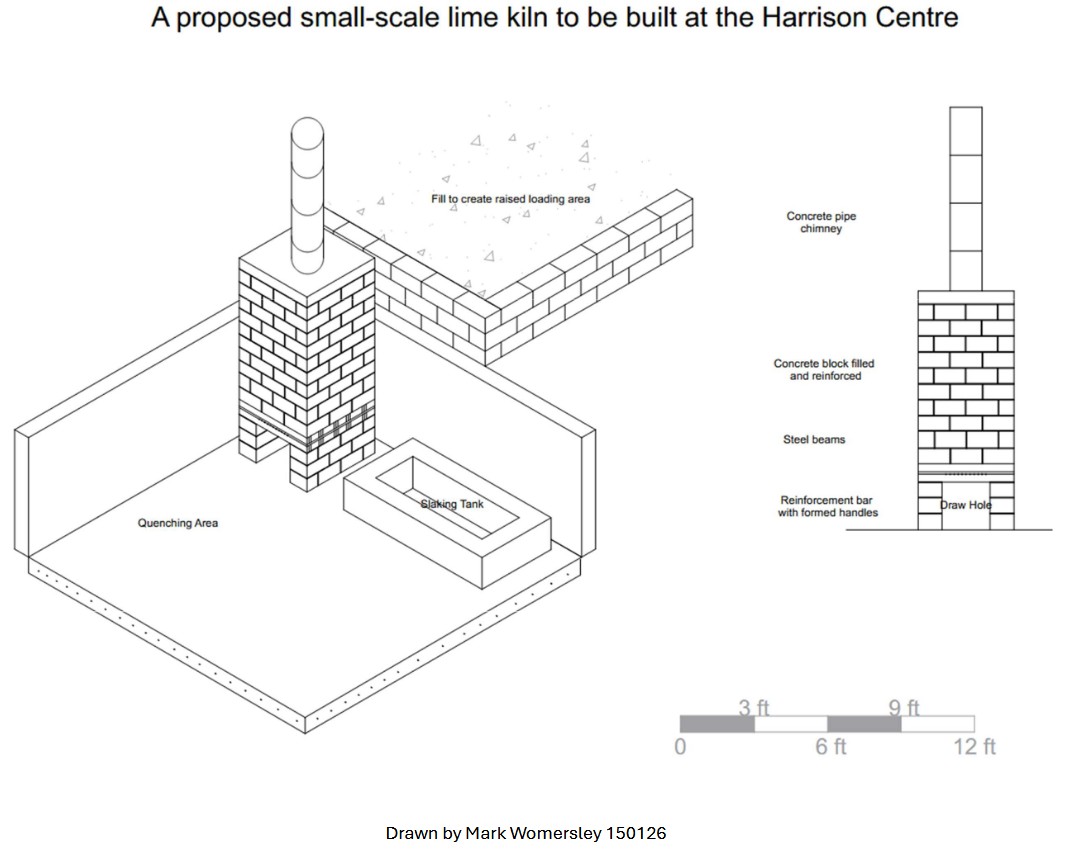

Because of time limitations (3 ½ days), we constructed the kiln shown in Figures 1 to 3 from 8” hollow blocks, which were then filled with reinforcement bars and concrete. The medium-term plan after the first burn is to construct an inner skin with fire brick bedded on lime mortar, tie the whole structure together with horizontal steel straps and render it with a lime, sand, molasses mix.

Figure 1. The remains of the Lime Kiln at Farley Bay

Figure 2. How the kiln may have looked.

Figure 3. Charcoal burning was found near the kiln site

The kiln is built on an 8” reinforced concrete base with an outer width and depth of 48” and is 7 ½ feet tall, excluding the chimney. There is an opening at the front of 24” high by 18” wide. Above this opening are five 4” deep steel I beams, a spacer, and another five I beams. These steels form the lintels to the front of the kiln, and the gap between them allowed the insertion of 16 crook-shaped reinforcement bars to hold the charcoal and lime above as it was charged by burning wood below it for approximately 3 ½ hours.

Figure 4. The design of the proposed Kiln.

The kiln was loaded with two large sacks of charcoal, followed by layers of limestone, approximately one ton and charcoal (eight more consisting of 5 smaller bags of ‘waste and 3 full bags). This completely filled the kiln, which we capped with a heavy steel plate for safety and to retain heat. After 24 hours, it was emptied, but it would be better to leave it for 36 hours to ensure all the charcoal is burnt before unloading.

Figures 5 to 9. The construction and loading of the kiln.

Once burned, it was raked out of the kiln base after removing the steel reinforcement bars to allow full discharge. Water was then added to promote the formation of a fine, hydrated powder that could be used after sieving out unburnt lime for slaking or transport to other sites on the island. The limestone released CO2 during combustion, forming quicklime (calcium oxide). When we quenched its thirst, it remained dry but turned into calcium hydroxide. The Calcium hydroxide was then passed through a 45-degree mesh screen to remove unburned lime and charcoal. Once added to water, this dry powder will fully slake and then, after maturing for 2 to 6 weeks, can be mixed with two to two and a half parts sharp sand to form a fat lime mortar that will just cure by absorbing CO2 back into itself to become calcium carbonate, binding the sand together. It can also be mixed with damp sand and left as a hot lime mortar for a few weeks before it is knocked back up and used. It should NEVER be used as a hot mortar, despite the UK fashion for such things.

Figures 10& 11. Discharging, quenching and turning the quicklime.

This work is part of a project funded by the Queen Elizabeth II Platinum Jubilee Commonwealth Heritage Skills Training Programme, funded by the Vinehill Trust.

Related Articles

The steps members of the Waterton’s Wall restoration team, with support from Mark Womersley, have been following to consolidate, conserve and repair this historic wall that represents the successful efforts of Charles Waterton to preserve the wildlife that lived on his estate near Wakefield in West Yorkshire.

1. Fill deep voids behind the wall’s facing stones with deep pointing work. The works involve …

Mark spent a day recording a historic timber-framed garden building at Woodsome Hall

Mark Womersley, as part of his voluntary work with the Yorkshire Vernacular Buildings Study Group, spent…

M Womersleys were delighted to offer a day of tutoring to those who attended the Wentworth Woodhouse Working Party

M Womersleys were delighted to offer a day of tutoring to those who attended the Wentworth Woodhouse…