Today, Mark was working with two tutors from the local technical college, to build a small trail lime kiln

Today, Mark was working with two tutors from the Samuel Jackman Prescod Institute, technical college, to build a small trail lime kiln, at Lears Quarry, Barbados. From the quarry, we used rubble coral stone and bedded it on a mortar made from hydrated lime and cement at a 1:1:6 mix. The aggregate consisted of the quarry’s crushed coral stone sands, their ¼” down and fine dust free grades. Tomorrow we will finish the build and burn the coral stone in the foreground of the picture using wood, charcoal, and a little coal.

Quicklime production stopped on the island in the early 1960’s, and M Womersleys on behalf of the Queen Elizabeth II, Platinum Jubilee Commonwealth Heritage Skills Training Programme, funded by the Hamish Ogston Foundation, working with the local college is trying to develop appropriate conservation mixes for the island’s historic buildings. The lime burn will give us the quick lime to slake, so that later on this month we can trial different mixes for building, plastering and render repair.

Related Articles

The steps members of the Waterton’s Wall restoration team, with support from Mark Womersley, have been following to consolidate, conserve and repair this historic wall that represents the successful efforts of Charles Waterton to preserve the wildlife that lived on his estate near Wakefield in West Yorkshire.

1. Fill deep voids behind the wall’s facing stones with deep pointing work. The works involve …

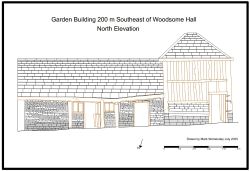

Mark spent a day recording a historic timber-framed garden building at Woodsome Hall

Mark Womersley, as part of his voluntary work with the Yorkshire Vernacular Buildings Study Group, spent…

M Womersleys were delighted to offer a day of tutoring to those who attended the Wentworth Woodhouse Working Party

M Womersleys were delighted to offer a day of tutoring to those who attended the Wentworth Woodhouse…